The tantalizing aroma of freshly baked bread, the irresistible crunch of potato chips, and the chilled perfection of a smoothie—all brought to you by the quiet hum of robots. The food processing industry stands on the brink of transformation thanks to advanced automated systems that promise not only efficiency but also impeccable safety and sustainability standards.

Consumers today expect more from their food: better quality, safer production, and greener manufacturing. These demands have set the stage for an industry-wide overhaul driven by technological advances. Automation is no longer just a buzzword; it’s the backbone of the future of food processing.

The Role of AI, ML, and IoT

Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) have become integral components in the transformation of food production. These technologies allow manufacturers to monitor operations in real-time, predict maintenance needs, and streamline processes to enhance efficiency and quality control measures.

The real-time monitoring capabilities provided by AI and IoT facilitate immediate responses to machinery faults or deviations in production. Machine Learning algorithms analyze historical data to predict future issues, ensuring timely maintenance and reducing downtime. This level of predictive insight not only boosts operational efficiency but also helps in achieving consistent product quality.

Further driving this revolution is adaptability. Automated systems can swiftly adjust to fluctuating market demands, offering manufacturers the agility to pivot production processes accordingly. This dynamic flexibility ensures a balance between demand and supply, thus preventing overproduction and waste while meeting consumer needs effectively.

Compliance with Hygiene Standards

Food safety remains a paramount concern in the industry. Automated systems significantly minimize human contact with food during processing, drastically reducing contamination risks. These systems are pivotal in complying with stringent hygiene standards, ensuring that the products reaching consumers are safe and healthy.

Automated quality inspection systems have also gained prominence. These systems utilize advanced sensors and imaging technologies to conduct rigorous checks for consistency, quality, and safety. The focus on innovative automation solutions addresses the industry’s stringent regulations, maintaining high standards of product integrity and consumer trust.

Investments in these systems reflect the industry’s commitment to mitigate risks associated with foodborne illnesses. By embedding robust safety measures within automated processing lines, manufacturers can uphold the highest hygiene standards, fostering consumer confidence in their products.

Reducing Waste and Energy Consumption

Sustainability has become a core mission for many food processing companies. The trend towards eco-friendly and resource-optimized automation systems aims to minimize waste and energy consumption. This shift is not just a response to regulatory pressures but also to growing consumer demand for environmentally responsible production practices.

Efficient resource management is a critical aspect of these systems. Automation enables precise control over production inputs, thereby reducing unnecessary waste. Energy-efficient machinery and protocols further ensure that the environmental footprint of food processing operations is minimized.

Manufacturers are increasingly embedding sustainability within their operations. This proactive approach aligns their production methods with both regulatory standards and consumer expectations, fostering a market that values ecological sensitivity alongside economic efficiency.

North America and Europe Lead the Way

North America and Europe have emerged as prominent markets for automated food processing systems. Leading companies like Schneider Electric SE, Rockwell Automation Inc., and Siemens AG are spearheading developments in these regions, setting benchmarks for innovation and efficiency.

These regions benefit from robust infrastructure, significant investments in technology, and favorable regulatory frameworks that encourage the adoption of advanced automation. This competitive edge positions North America and Europe as pioneers in the global food processing landscape, setting trends in technological integration and sustainable practices.

Asia-Pacific and Emerging Markets

Meanwhile, regions such as Asia-Pacific, Latin America, and the Middle East are witnessing substantial growth opportunities. Key players including Mitsubishi Electric Corporation and Yokogawa Electric Corporation are expanding their presence, tapping into the burgeoning demand for automated food processing solutions in these markets.

The rapid urbanization and economic growth in these areas are driving the need for efficient and safe food processing. These regions provide fertile ground for innovation and expansion, highlighting the dynamic potential of automated systems to meet diverse market needs and enhance food security.

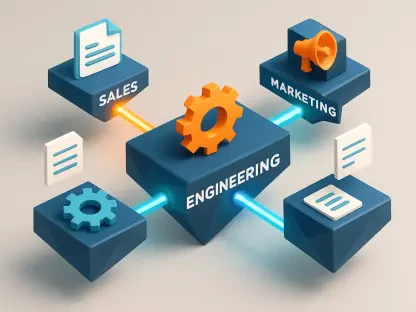

Strategic Insights for Stakeholders

For stakeholders navigating this evolving landscape, strategic insights are invaluable. Analyzing market trends and opportunities from 2025 to 2032 offers a roadmap for identifying and capitalizing on potential growth areas. These insights guide decision-making processes, facilitating competitive positioning and market penetration.

Incorporating region-specific analysis and competitor strategies can bolster stakeholders’ efforts in achieving their business objectives. Understanding the competitive landscape empowers stakeholders to refine their approaches, ensuring sustained growth and market relevance.

Methodological rigor, combining qualitative and quantitative research, adds depth to the analysis. Perspectives from industry specialists further enrich the findings, providing a comprehensive view of the Automated Food Processing Systems market dynamics.

Conclusion

The Automated Food Processing Systems market is on a trajectory of unprecedented growth, driven by technological advancements, enhanced food safety measures, and sustainable practices. These developments signal a transformative era for the industry, where agility and innovation are paramount. Key players and stakeholders must seize opportunities and navigate challenges with strategic foresight, positioning themselves to thrive in this rapidly evolving market landscape.

As the industry continues to embrace automation, the impact on food processing will be profound. The fusion of technology, safety, and sustainability is set to redefine how food is produced, ensuring that the future of food processing is efficient, safe, and eco-friendly. The transformational journey ahead promises not only growth but also a more responsible and resilient food industry.