As the affordable housing boom sweeps across North America, the construction industry faces a complex web of challenges and opportunities. I had the privilege of sitting down with Simon Glairy, a renowned expert in insurance and Insurtech, with a deep focus on risk management and AI-driven risk assessment. With years of experience navigating the evolving landscape of construction risks, Simon offers invaluable insights into the pressures of rapid development, the shift to innovative building methods, and the growing threats of cyber and fraud risks. Our conversation explores how speed and technology are reshaping the industry, the hidden pitfalls of cutting-edge approaches, and the strategies firms can adopt to stay ahead of emerging exposures.

How is the surge in affordable housing construction reshaping the industry, and what’s driving this rapid growth?

The surge in affordable housing construction is really a response to a critical need across North America—there’s a massive demand for accessible homes, fueled by population growth, urbanization, and government incentives. Developers are under immense pressure to deliver quickly, often supported by policies or funding that prioritize speed. But this rush is reshaping the industry by pushing firms to adopt faster build cycles and innovative methods, sometimes at the expense of traditional quality checks. It’s a double-edged sword: we’re building more, but we’re also seeing new risks emerge from this pace.

What impact does the emphasis on speed have on the quality of construction projects?

Speed is a major factor in compromising quality. When timelines are compressed, there’s less time for thorough planning, inspections, or even proper training for workers. Corners get cut, whether it’s in material selection or construction techniques, and that often leads to defects. What’s troubling is that many of these issues don’t surface right away—they might take five or six years to become apparent, leaving builders and developers exposed to costly repairs or lawsuits down the road.

Can you elaborate on how labor shortages are contributing to these quality concerns?

Absolutely. Labor shortages mean that many projects are staffed with less experienced workers or crews stretched thin across multiple sites. Without skilled hands on deck, mistakes happen more frequently—think improper installations or missed safety protocols. This directly ties into higher defect rates, and it’s a systemic issue because the demand for workers is outpacing the supply. It’s not just about filling positions; it’s about having the right expertise, which is increasingly hard to come by.

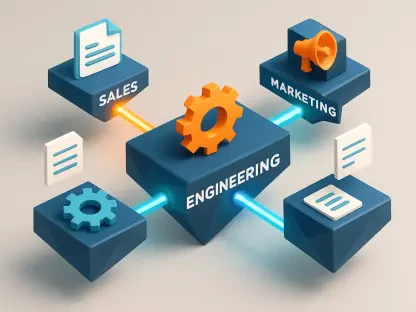

How does the shift to prefabricated construction offer solutions to some of these challenges, and what new risks does it introduce?

Prefabrication is a game-changer for addressing labor shortages and speeding up builds. By creating components in a controlled factory setting, you get consistency and often better safety conditions compared to on-site work. But it introduces logistical headaches. You’re turning construction into a manufacturing process, which means coordinating shipping, storage, and assembly across potentially vast distances. If pieces don’t fit once they’re on-site, you’ve got delays and added costs. Plus, the risk doesn’t disappear—it just shifts to different stages, like transport or supply chain disruptions.

What does this shift mean for insurance needs in construction projects using prefabricated components?

Insurance for prefabricated construction has to be much more dynamic. Coverage needs to track materials from the factory floor to the final assembly on-site, accounting for risks at every step—damage during shipping, theft, or even delays that impact the project timeline. It’s a more complex puzzle than traditional construction, where risks are mostly site-specific. Brokers and insurers need to tailor policies to cover these unique exposures, often spanning international supply chains, which requires a deeper understanding of the process.

Turning to technology, why are developers leaning so heavily on innovations like robotics and AI in affordable housing projects?

Developers are turning to tech like robotics and AI because they promise efficiency in a highly competitive, low-margin environment. These tools can automate repetitive tasks, optimize material use, and even predict project risks before they happen. With the pressure to build quickly and cheaply, tech offers a way to scale operations without necessarily scaling costs proportionally. It’s about staying competitive—without these advancements, many firms couldn’t meet the current demand.

What are some of the hidden downsides to adopting these technologies in construction?

The downsides often come down to cost and longevity. Upfront investment in tech is steep, which is tough in a low-bid world where every dollar counts. More critically, the lifespan of some technologies doesn’t match the buildings they’re used to create. Imagine embedding a smart system in a structure meant to last 50 years, but the tech becomes obsolete or fails in just a decade. That creates maintenance headaches and financial burdens—often unclear who foots the bill, whether it’s the developer, owner, or insurer.

How has the increased use of digital tools opened up construction firms to cyber risks?

As construction firms digitize—think project management software, payment systems, or tenant data storage—they become prime targets for cyber threats. Ransomware and data breaches are spiking because these systems often hold sensitive financial or operational information. A single attack can lock a firm out of critical systems for days or weeks, stalling projects and costing a fortune in downtime. It’s a risk that’s grown exponentially as more processes move online, and many firms are still catching up to the reality of this threat.

What can smaller construction firms do to protect themselves against these cyber threats, given their limited resources?

Smaller firms face a tougher battle because they often lack the budget for robust cybersecurity. But there are practical steps they can take—starting with basic training for staff to recognize phishing emails or suspicious activity. Investing in affordable, off-the-shelf security software can help, as can regular backups of critical data to minimize downtime after an attack. Partnering with insurers or brokers who offer cyber risk guidance is also key. It’s about building a culture of awareness, even if you can’t afford a full IT department.

Lastly, what is your forecast for the future of risk management in the construction industry as these trends continue to evolve?

I think risk management in construction is going to become even more integrated with technology and data. We’ll see AI and predictive analytics play a bigger role in identifying risks before they materialize, whether it’s spotting potential defects or flagging cyber vulnerabilities. At the same time, I expect insurers to refine their offerings, creating more tailored policies for emerging methods like prefabrication. But the human element—training, oversight, and collaboration—will remain critical. The industry will need to balance innovation with resilience, ensuring that speed doesn’t come at the cost of sustainability or safety.