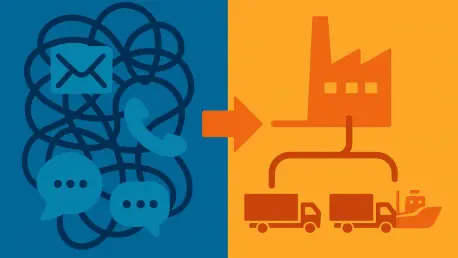

We are joined today by Simon Glairy, a distinguished expert in risk management and the application of AI in complex industries. Global trade, a system vital to our economy, remarkably still operates on a fragmented network of emails, messages, and phone calls. We will explore how new agentic AI platforms, like the one developed by Didero, are promising to bring order to this chaos by putting manufacturing procurement on autopilot. Our discussion will delve into how this technology translates unstructured communication into automated actions, the practicalities of integrating it with existing enterprise systems, and the specific challenges it solves within the intricate supply chain for manufacturers and distributors.

You’ve noted that global trade relies on fragmented communications like emails and WeChat. Could you share a specific example of how Didero’s AI ingests this unstructured data and translates it into an automated task, such as updating a purchase order, without human intervention?

Certainly. Imagine a procurement manager at a company like Footprint, which makes plant-based packaging, is waiting on a shipment. Their supplier in Asia sends a message on WeChat, not even a formal email, saying something like, “Regarding PO 789, there’s a port delay. New ETA is three days later.” In the past, this would sit in an inbox until someone read it, understood it, and then manually logged into their ERP system to update the delivery date. Didero’s agentic AI, however, is constantly monitoring these channels. It would immediately parse that natural language message, identify the purchase order number, understand the context of a delay, calculate the new arrival date, and then automatically update that specific field in the company’s system of record. No human finger ever has to touch a keyboard for that task; the entire loop from communication to system update is closed by the AI.

Didero is described as an agentic AI layer that sits on top of a company’s existing ERP system. Could you walk us through the practical steps of this integration and explain how you handle the complexities of coordinating between your platform and a client’s established systems of record?

This is the most critical part of making the technology work in the real world. The integration isn’t a simple plug-and-play. First, the AI layer connects to the client’s core ERP system through APIs, gaining read-and-write access to procurement data. The next step is connecting to the communication channels—the actual emails and WeChat accounts where global trade happens. The real complexity, and the platform’s core value, is in the coordination. The AI agent acts as an intelligent intermediary; it reads a supplier email about a price change, then cross-references the existing purchase order in the ERP to validate it before making any changes. It’s not just blindly executing tasks; it’s making decisions based on the established system of record, ensuring it doesn’t create data conflicts or overwrite critical information. This prevents the classic “garbage in, garbage out” problem by maintaining the ERP as the single source of truth.

The goal of automating procurement from the initial need for a good to the final payment is ambitious. For a client in the manufacturing sector, what are the most difficult steps in that workflow to put on autopilot, and what metrics best demonstrate the platform’s success?

The most difficult step is undoubtedly the negotiation phase. Sourcing a new supplier or negotiating pricing for raw materials involves nuance, relationship building, and strategic trade-offs that are harder for an AI to handle than simple order tracking. While an AI can compare quotes, the human element of building trust or navigating complex terms is a significant hurdle. Automating payment reconciliation is also challenging due to discrepancies between invoices, purchase orders, and receiving documents. The clearest metric for success is “cycle time”—the time elapsed from identifying a need to the final payment. Success would also be measured by a reduction in manual interventions, say, a 70% decrease in the number of times a procurement specialist has to manually update the ERP. Another key metric is cost savings, both from better-negotiated prices and from dramatically reduced overhead for the procurement team.

The AI procurement space includes tools that streamline corporate purchasing and others that help smaller brands source from manufacturers. How does Didero’s specific focus on the supply chain for manufacturers and distributors address a different set of challenges, and what capabilities make it essential for them?

This is a key distinction. Tools like Zip or Oro Labs are fantastic for corporate purchasing—think ordering laptops or software licenses. That’s a relatively standardized process. Didero is tackling a much messier world: the direct supply chain for physical goods. A manufacturer isn’t just buying a finished product; they’re sourcing raw materials, custom components, and inputs from a global network of suppliers. The challenges here involve managing multi-stage production timelines, fluctuating raw material costs, international logistics, and quality control. What makes a platform like Didero essential is its ability to manage this entire complex workflow, from the initial quote for a specific grade of steel to tracking its shipment across an ocean and processing the final payment. It’s built for the non-stop, dynamic communication that defines manufacturing, not the periodic, predictable nature of corporate procurement.

What is your forecast for the future of agentic AI in the global supply chain over the next five years?

Over the next five years, I forecast that agentic AI will become the standard operating system for global supply chain management, not just a niche tool. We’ll move from AI as a passive assistant that flags issues to AI as a proactive agent that autonomously resolves them. Instead of just alerting you to a shipping delay, the AI will have already sourced an alternative carrier, negotiated the price, and rebooked the shipment to minimize disruption, all before a human manager even sees the initial alert. Companies like Didero, backed by significant funding like their $30 million Series A, are laying the groundwork for this. The result will be more resilient, efficient, and transparent supply chains, where human expertise is elevated from managing mundane tasks to overseeing and refining the strategies these powerful AI agents execute.